一、 适用范围

1、适用于现浇和预制的混凝土、预应力钢筋混凝土及外掺粉煤灰混凝土,对普通硅酸盐水泥、矿渣硅酸盐水泥和火山灰硅酸盐水泥等均有较好的适应性。本产品对混凝土冬季施工效果更为显著。

2、 适用于自然养护的混凝土工程及制品。本品减水增强作用显著,早期效果尤佳,可大大加快模板和场地周转,缩短工期。

二、 主要性能

1、本产品为灰色粉剂,无毒、无臭、不燃,对钢筋无锈蚀作用。

2、该产品是一种复合早强减水剂,既可提高混凝土工程和制品的早期强度,又可节约水泥。

3、在0~20℃平均气温下,掺加2%的该产品,可使混凝土一天抗压强度提高80%以上,三天抗压强度提高60%以上,七天抗压强度提高30%以上,二十八天抗压强度提高15%以上。

4、对于一般塑料性混凝土掺加2%的该早强减水剂,可减少拌和用水20%以上。

5、掺入本产品以后,混凝土各种物理性能均有良好的改善。

6、在坍落度和强度基本相同的情况下,可节约水泥10%以上。

三、 掺MNC-A3型早强减水剂混凝土性能指标

|

检验项目

|

企标 |

检测结果 |

检测项目

|

企标 |

检测结果 | ||

|

减水率(%)

|

≥12 |

13.2 |

抗压强度比(%)

|

1d |

≥180 |

185 | |

|

泌水率比(%)

|

≤90 |

78 |

3d |

≥160 |

164 | ||

|

含气量(%)

|

≤3.0 |

2.7 |

7d |

≥130 |

135 | ||

|

凝结时间差(min) |

初凝 |

-90~+120

|

+28 |

28d |

≥115 |

118 | |

|

终凝 |

+37 |

收缩率比(%)

|

28d |

≤135 |

128

| ||

|

对钢筋锈蚀作用

|

无 |

无 | |||||

|

注:检测掺量2%(以水泥用量计)。

| |||||||

本产品的掺量范围为2 %,推荐掺量为2%(以水泥用量计)。

五、 使用方法

1、本产品可与水泥一起加入搅拌机,计量必须准确。

2、为搅拌均匀,应延长搅拌时间30秒。

六、 包装、运输、贮存

1、本品采用内衬塑料袋,外编织袋包装。每袋净重25㎏±0.13㎏或50㎏±0.25㎏。

2、运输时谨防受潮和遇锋利物,以防止破包。

3、应贮存在通风、干燥的专用仓库内,有效期为二年,超过有效期经检测合格后仍可使用。若受潮结块需烘干粉碎后使用。

|

MNC-A3 SERIES EARLY-STRENGTH SUPERPLATICISER | |||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

APPLICATION

The blend dosage normally ranges from 2 %.The standard blend dosage is established at 2%. DIRECTIONS 1. The powdery agent can be agitated together with cement. Accurate measurement is essential. 2. A 30-second agitation is required to achieve good homogeneity. PACKGING,TRANSPORTATION AND STORAGE 1. Woven fabric bag with plastic liner.Net weight:25kg 0.13 or 50kg 0.25. 2. Cautions should be taken to prevent from being torn by sharp-ended objects while packages are transferred or delivered. 3. It should be stored in a dedicated warehouse that is well-ventilated and dry. It remains effective for two years. At the expration, re-use is allowed if the testing results fall within the established range. In case of humidity contamination, re-use is allowed after drying and crushing. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||

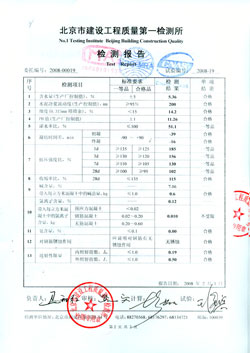

| 检测报告 | |